Clean Energy

Creating eco-friendly energy for a cleaner future

Creating eco-friendly energy for a cleaner future

GS EPS makes a sustainable future with eco-friendly energy, such as LNG, biomass, and photovoltaic power generation, and also continues to develop technologies and invest in facilities to expand the transition to eco-friendly power generation for achieving Net-zero.

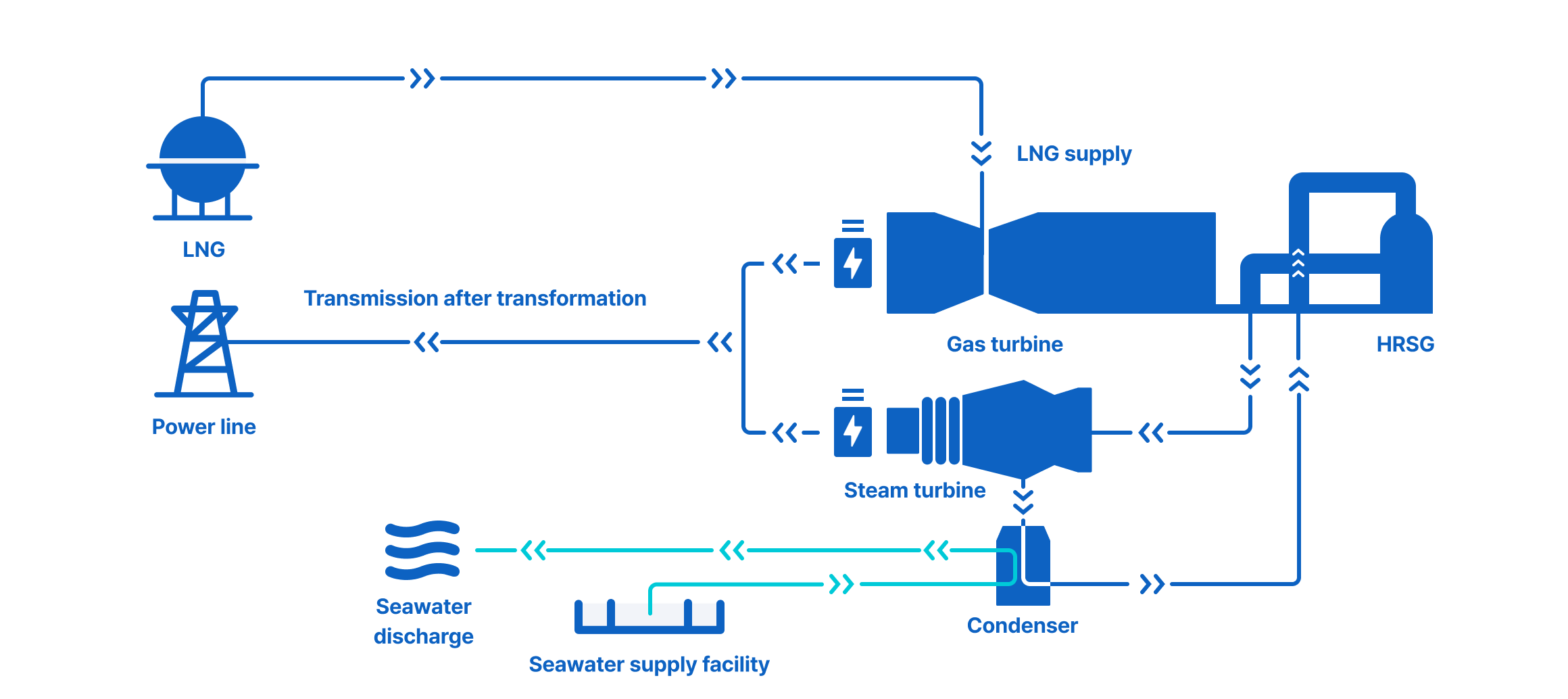

LNG, a natural gas, is an eco-friendly fuel that induces fewer air pollutants and carbon emissions than coal and oil. GS EPS utilizes LNG as a fuel to produce green and low-carbon energy for a clean environment in the future.

We build a stable portfolio through fuel supply contracts, including direct gas import and average rate systems.

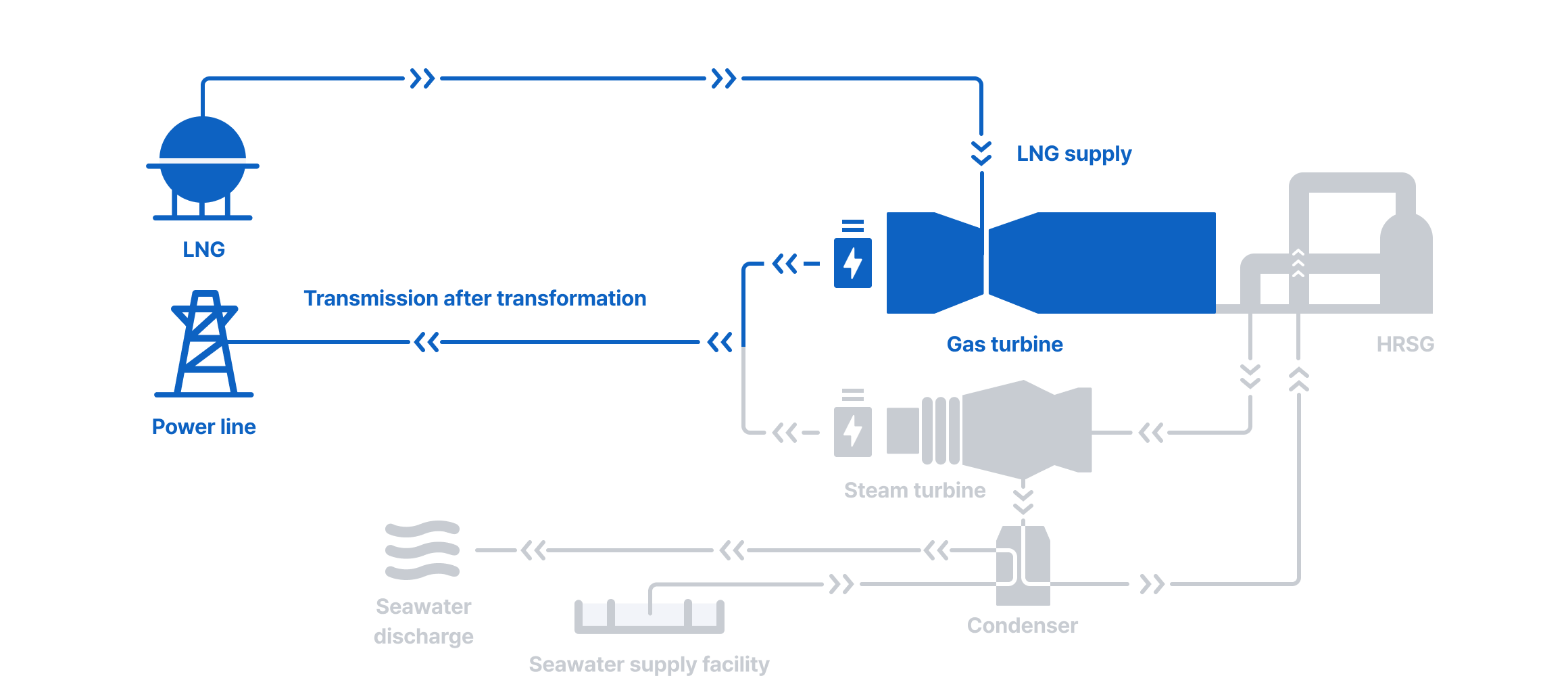

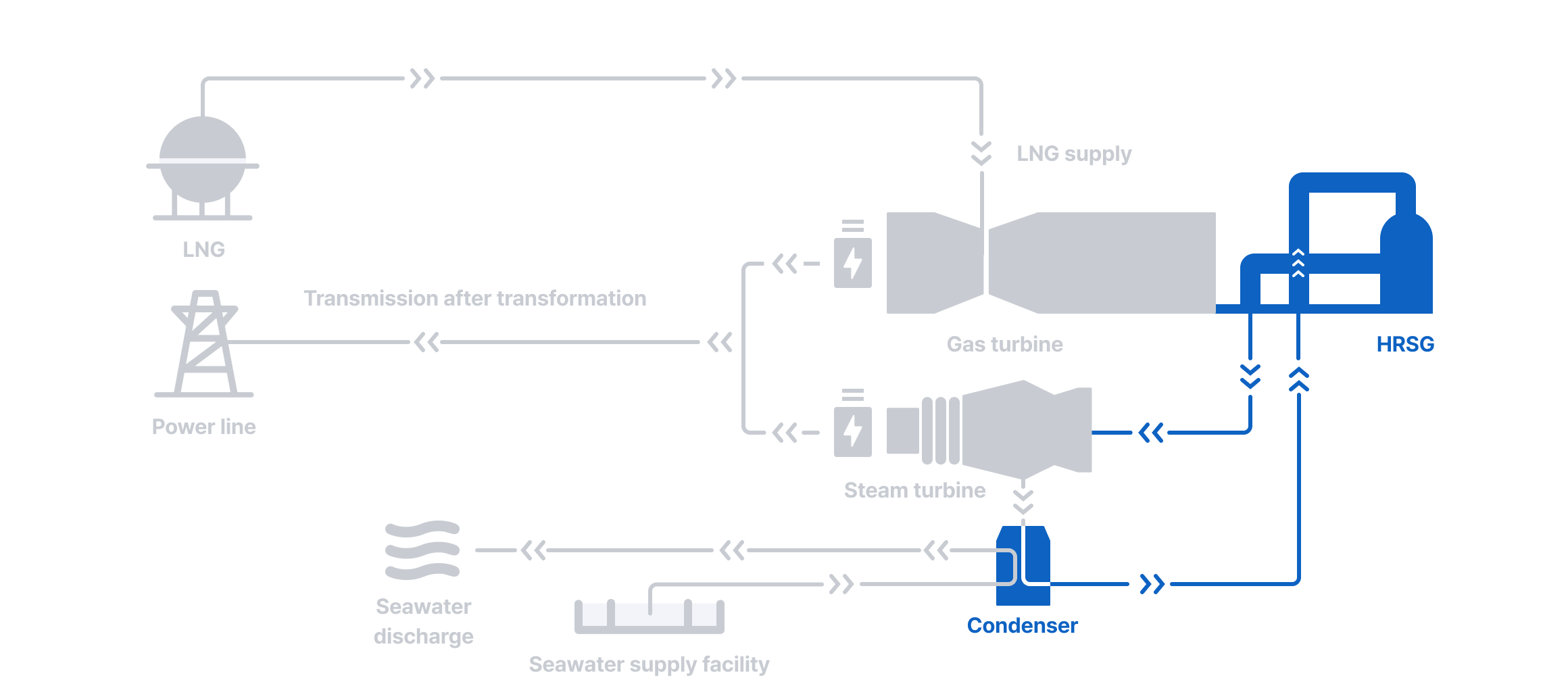

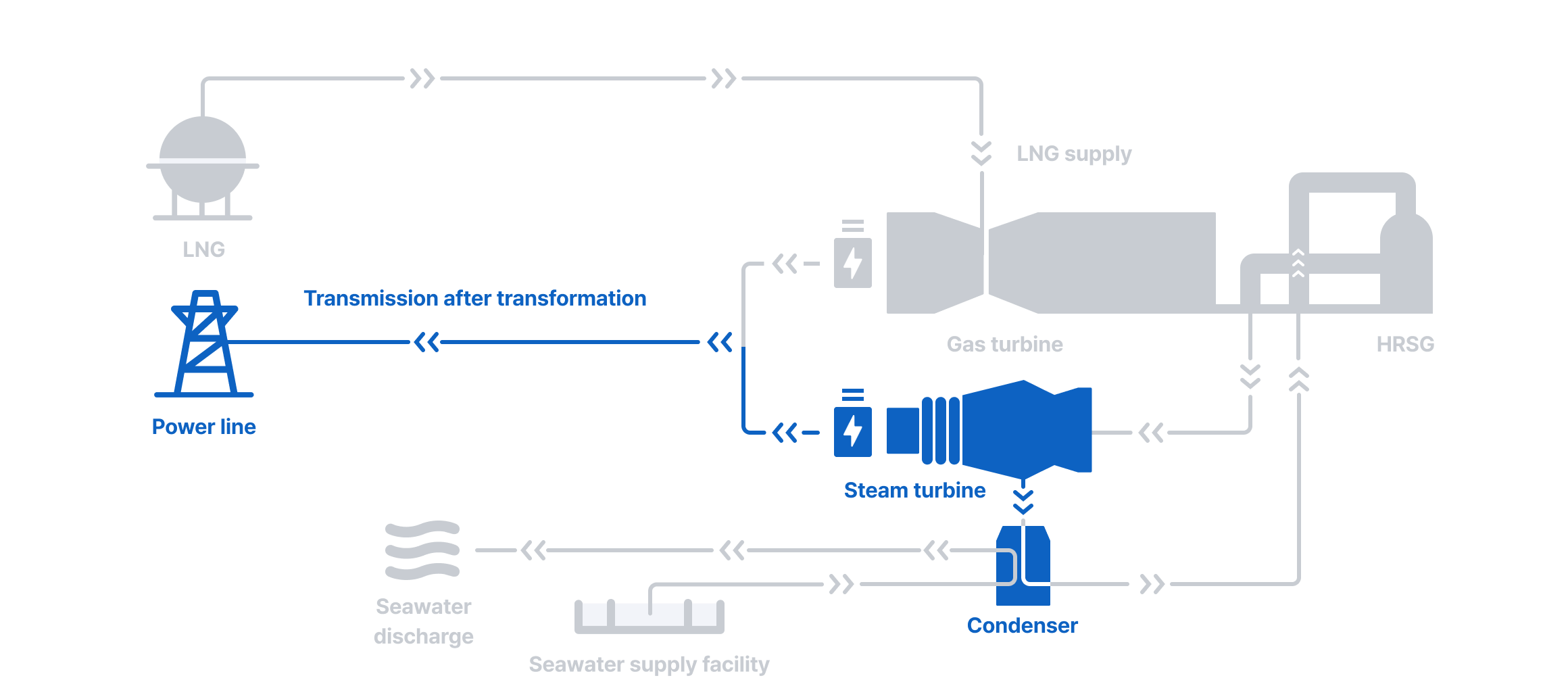

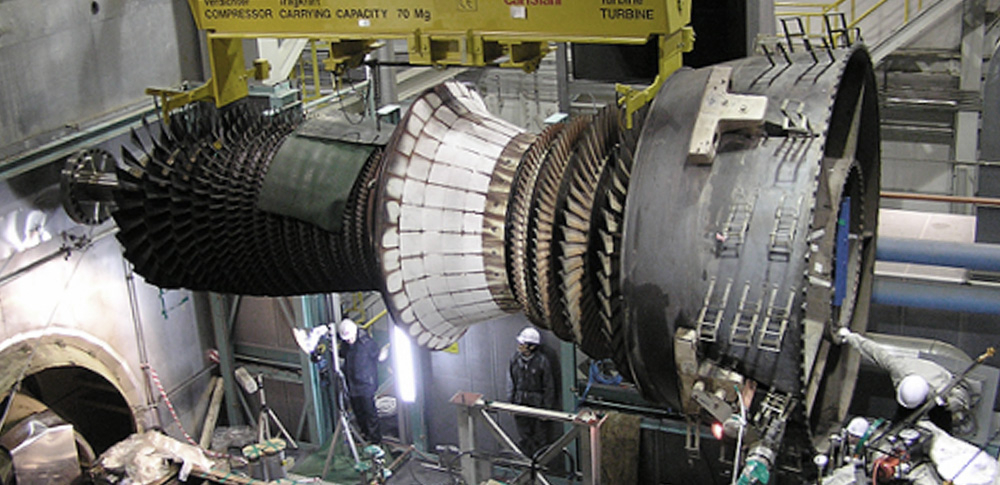

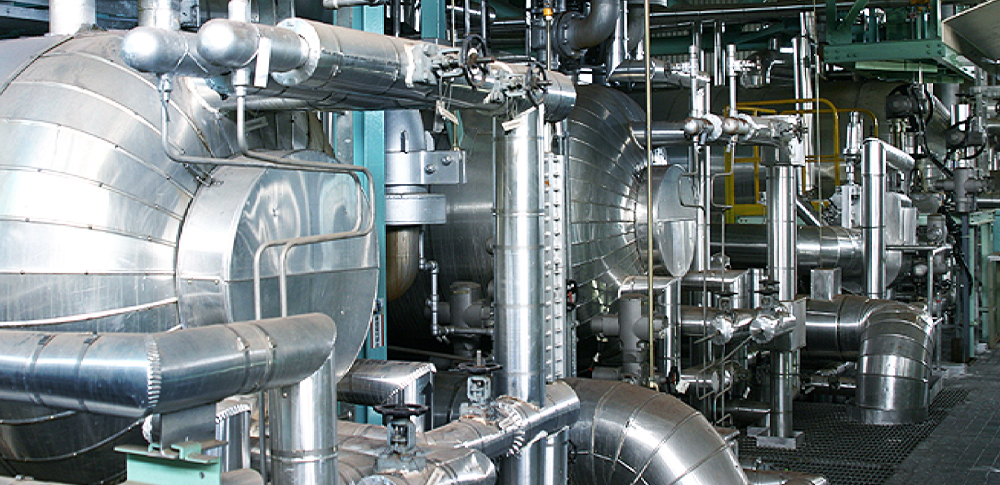

GS EPS generates and supplies eco-friendly energy with the highest efficiency level in Korea by operating high-efficiency combined cycle power plants with a total capacity of 2,400MW.

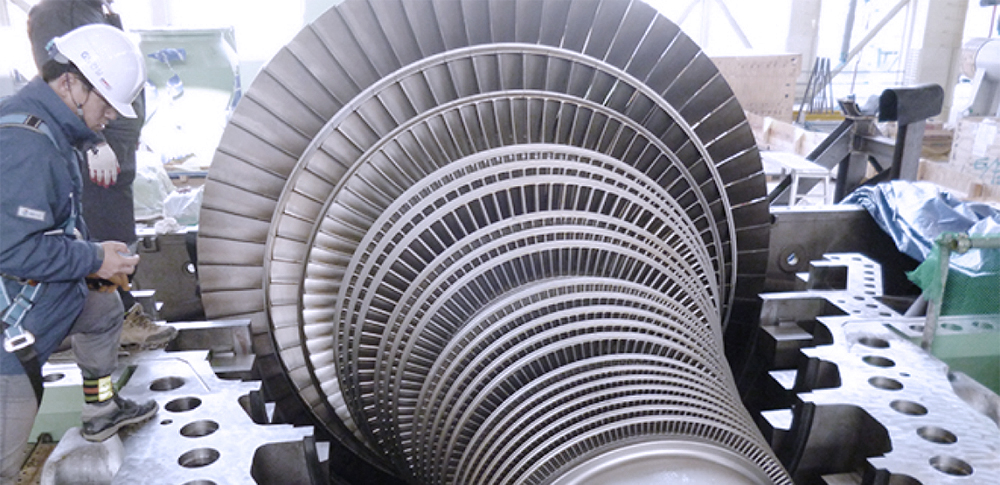

LNG combined cycle power plants burn natural gas for the first generation, and simultaneously the exhaust heat from the first step makes steam. The high-temperature and high-pressure steam spins the turbine to generate secondary high-efficiency electricity.

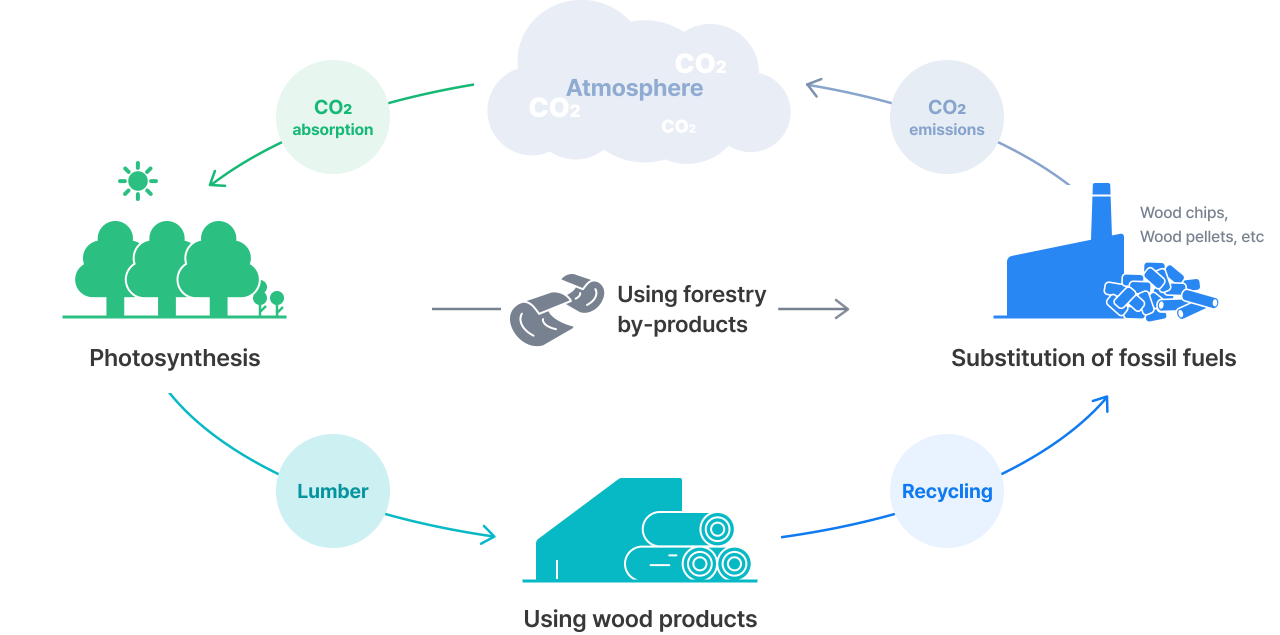

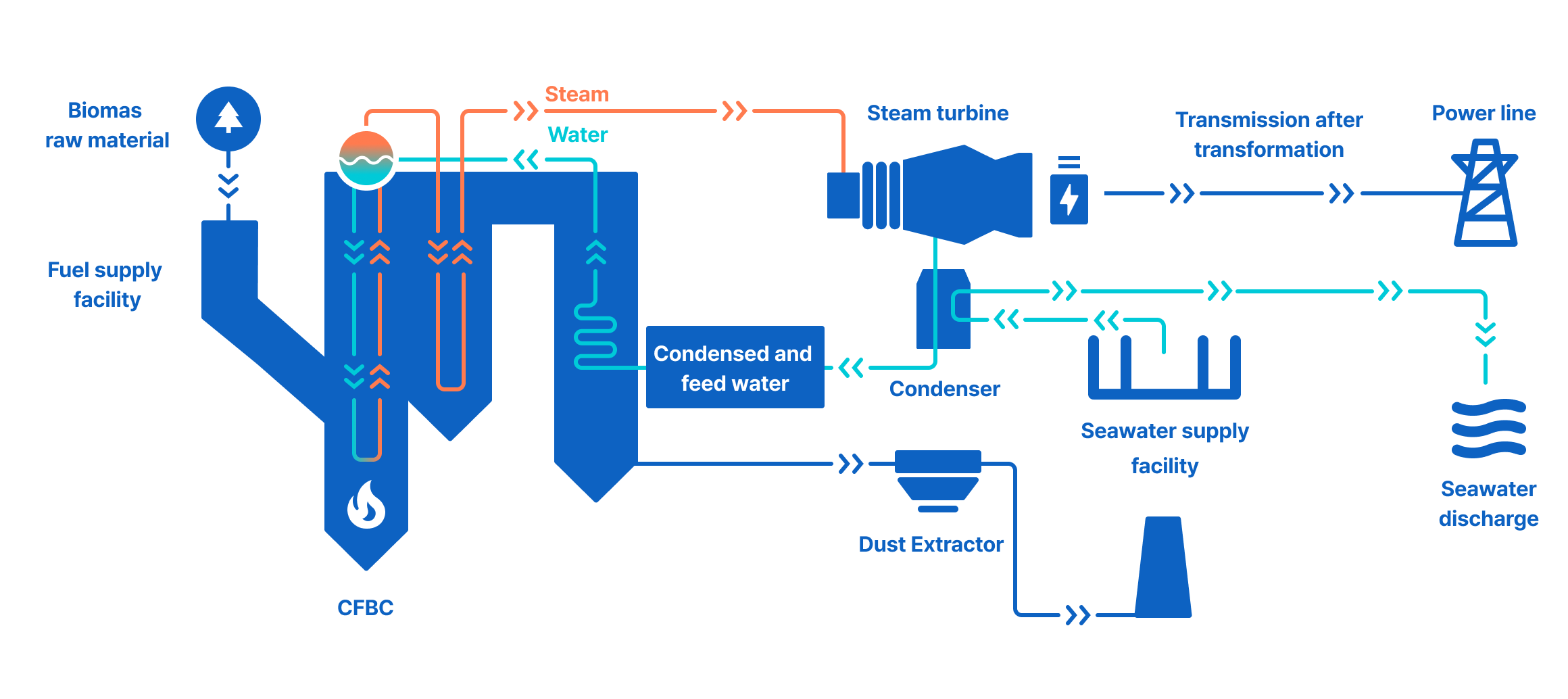

Biomass is an eco-friendly energy source that uses resources more efficiently and minimizes the impact of global warming. It is because carbon dioxide during fuel use is absorbed through photosynthesis and converted into new biomass, creating a carbon cycle.

GS EPS is advancing net-zero and producing sustainable clean energy through eco-friendly biomass power generation.

GS EPS constructed Biomass Unit 2 in 2021 and now operates 210MW of biomass plants.

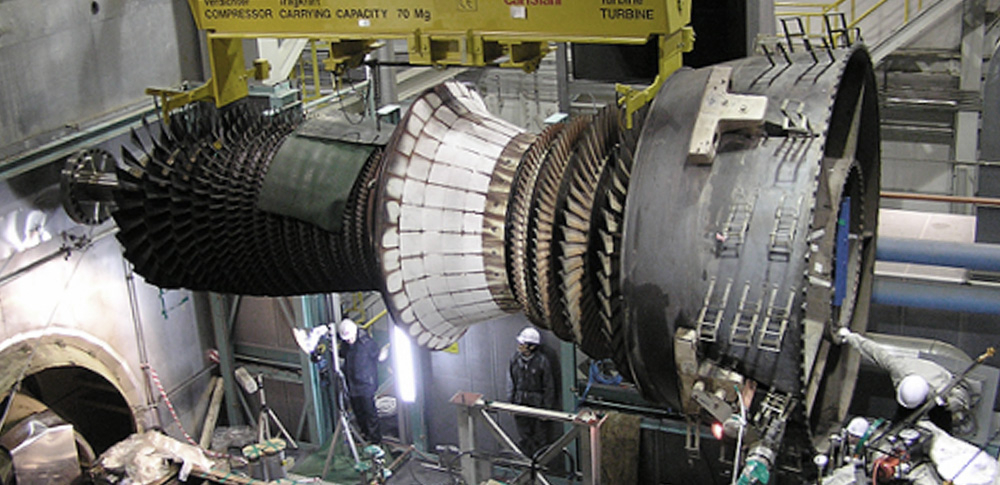

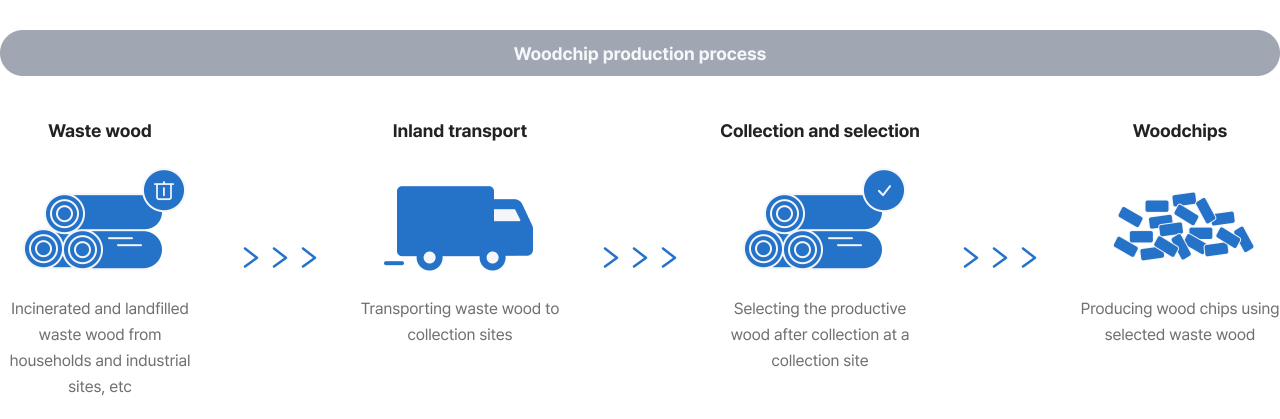

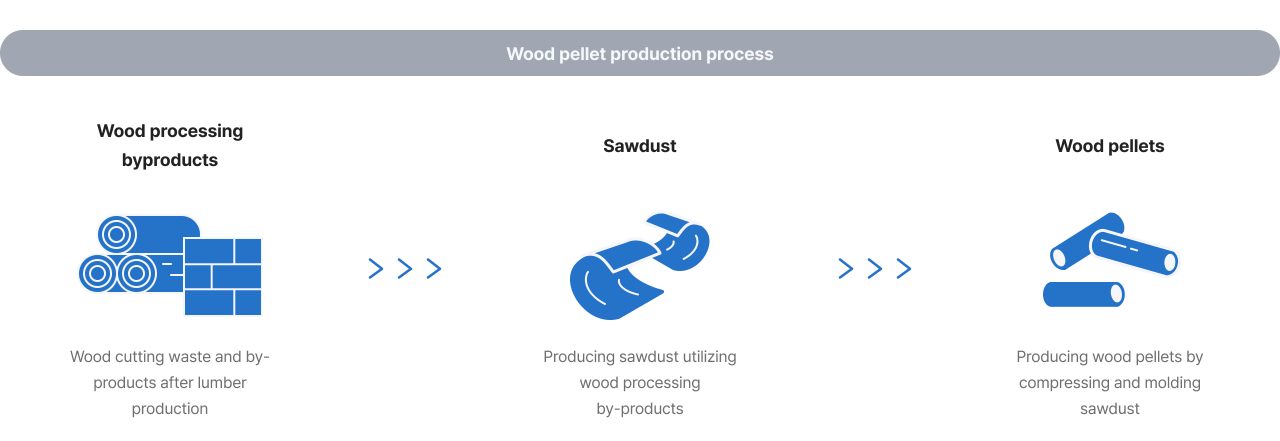

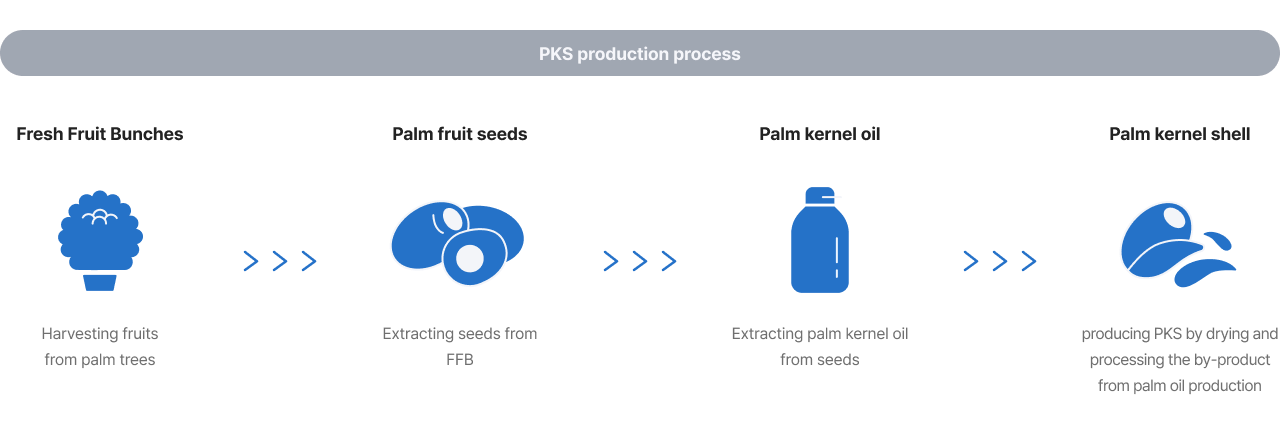

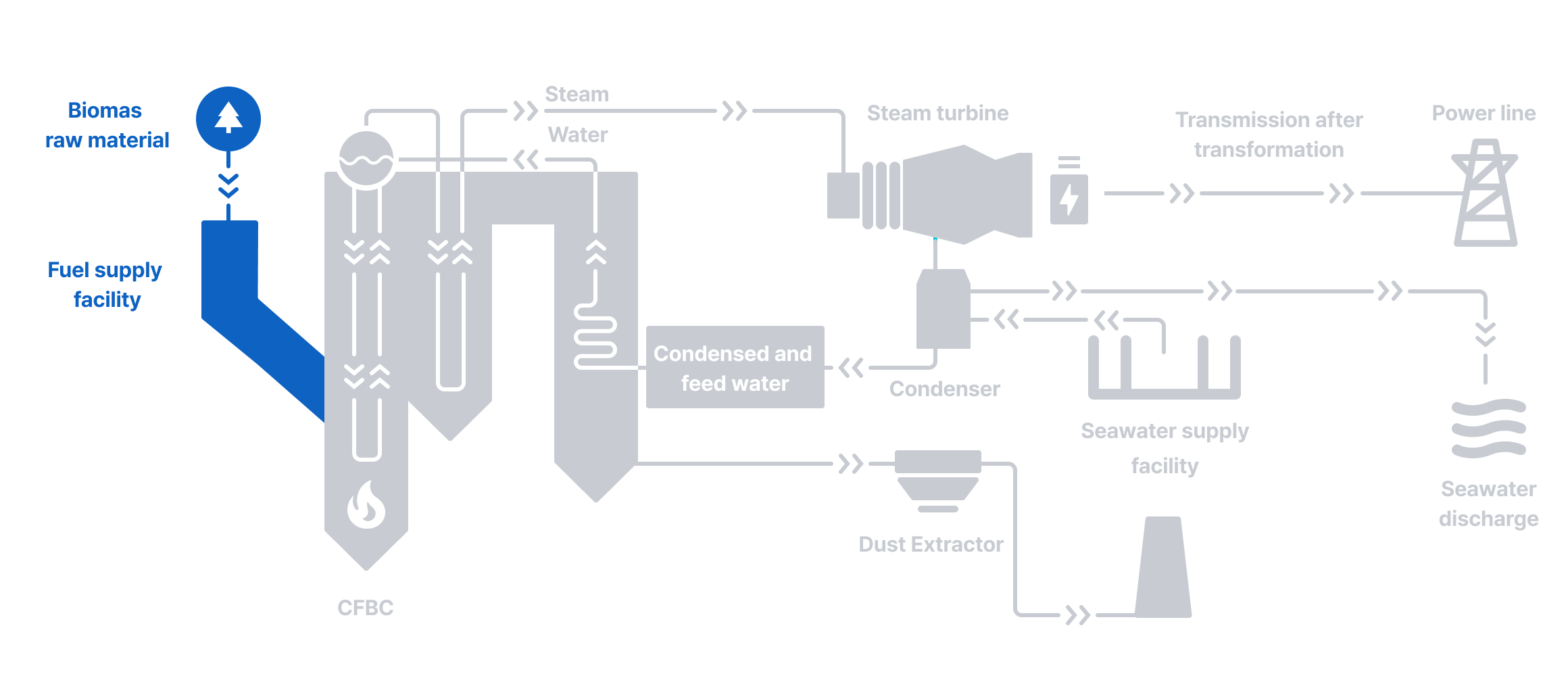

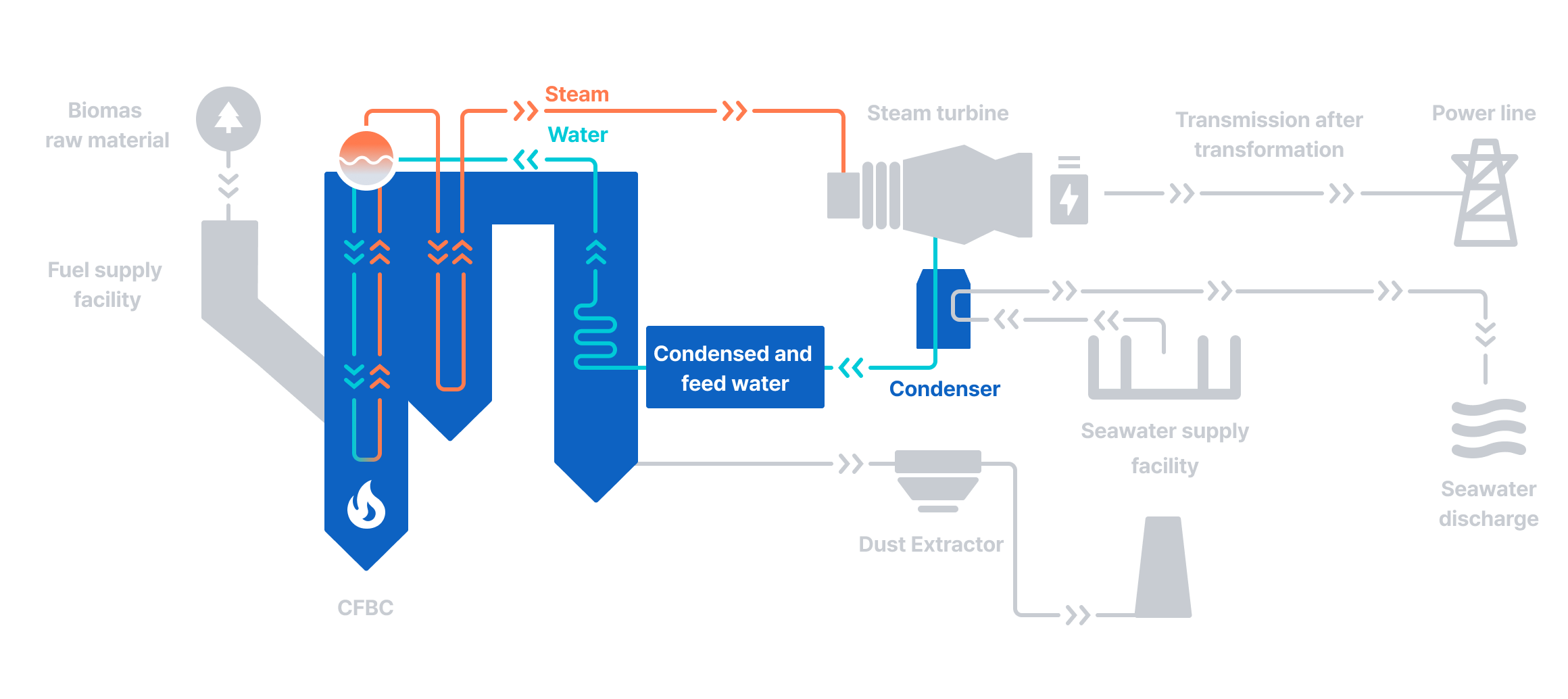

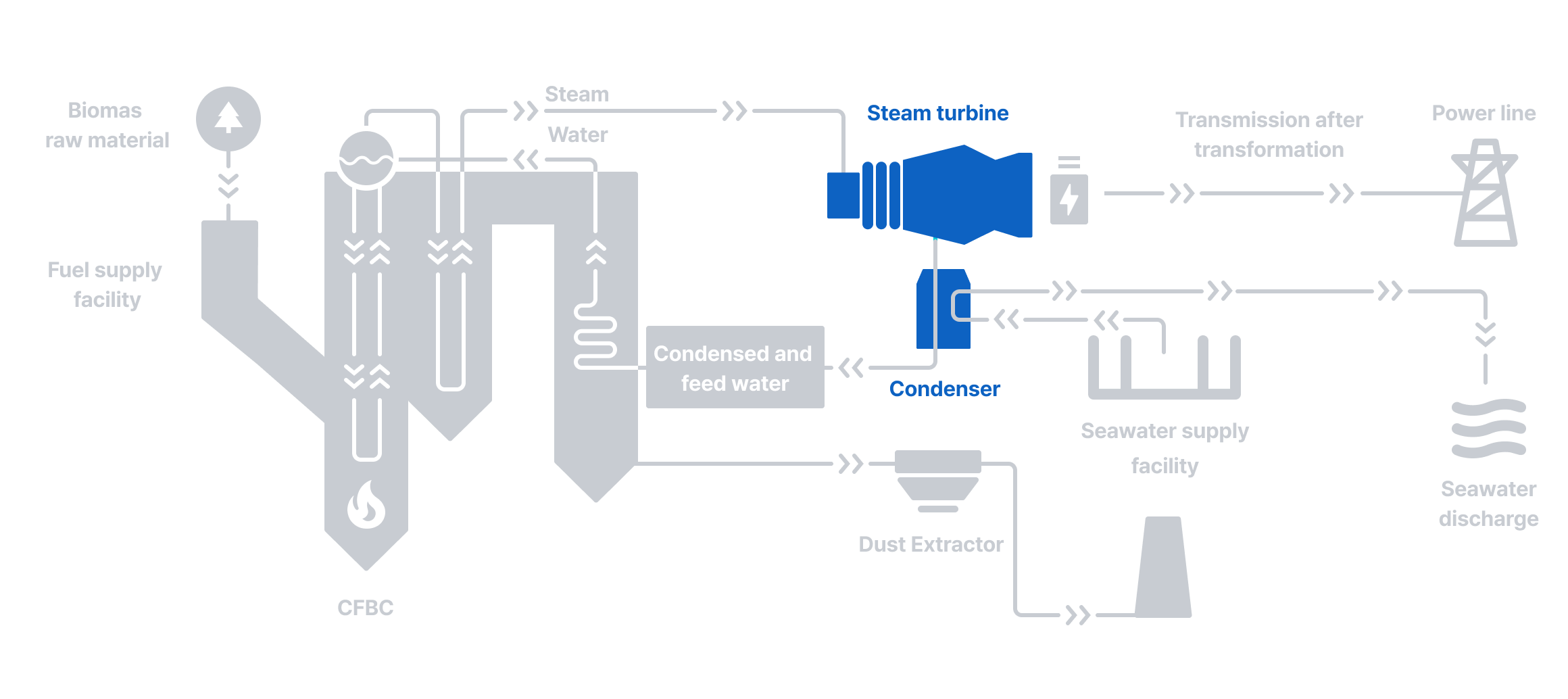

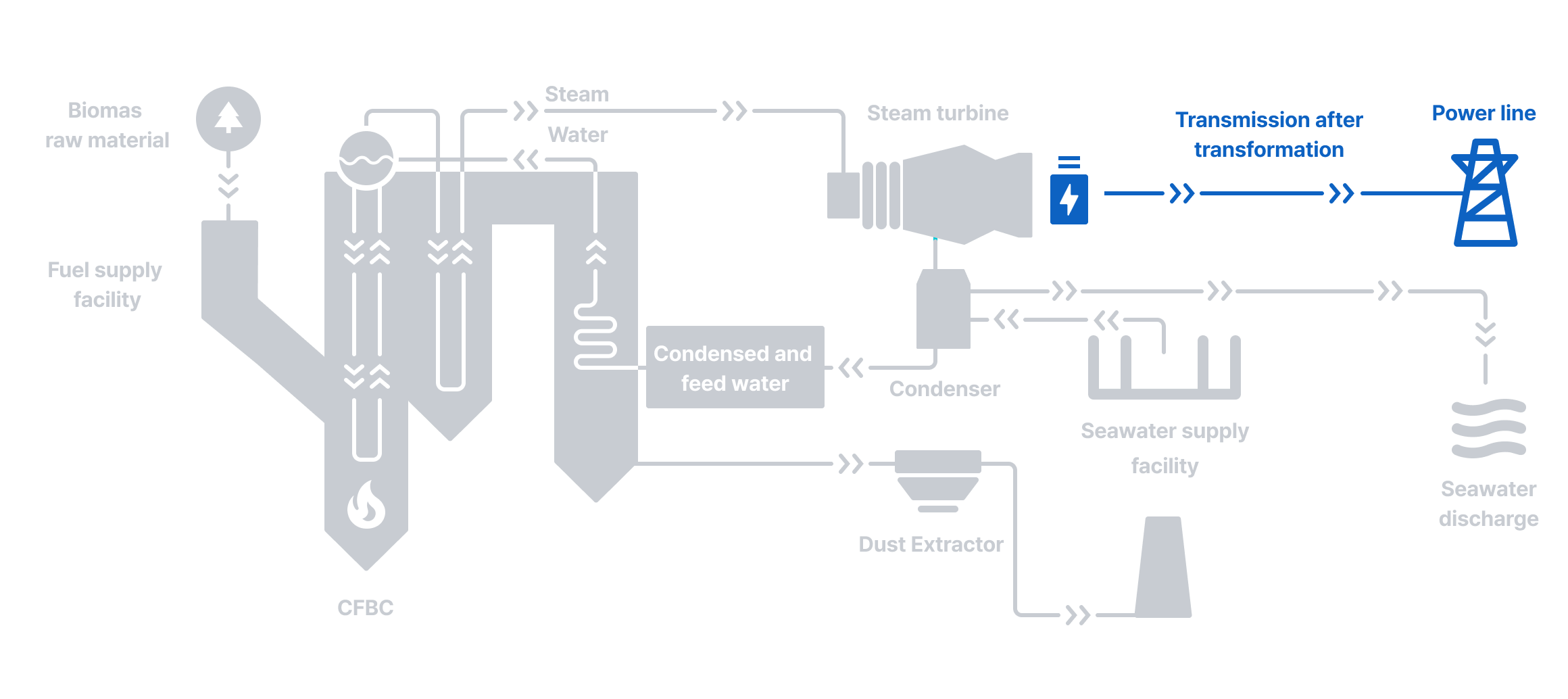

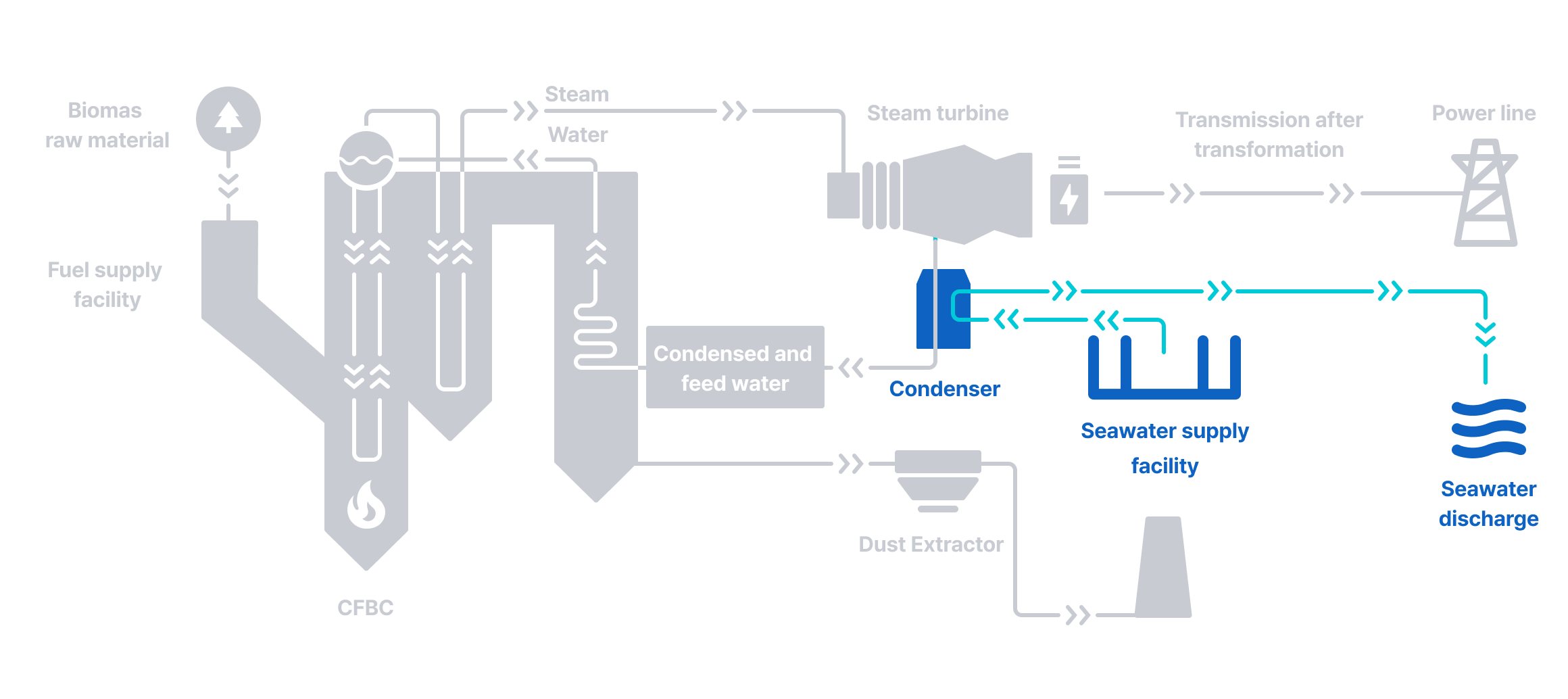

In biomass power generation, renewable raw materials such as plants and industrial by-products are burned to produce steam. This steam rotates turbines to produce electricity.

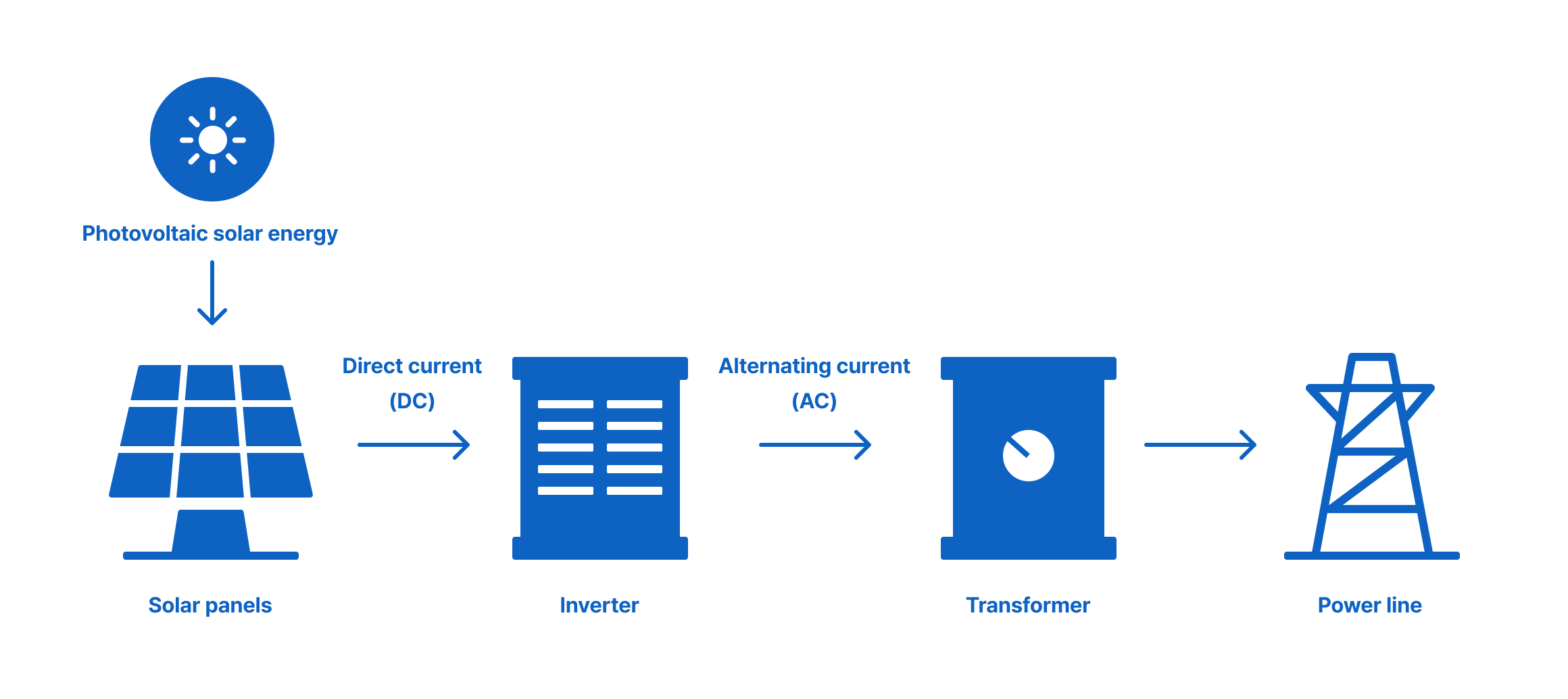

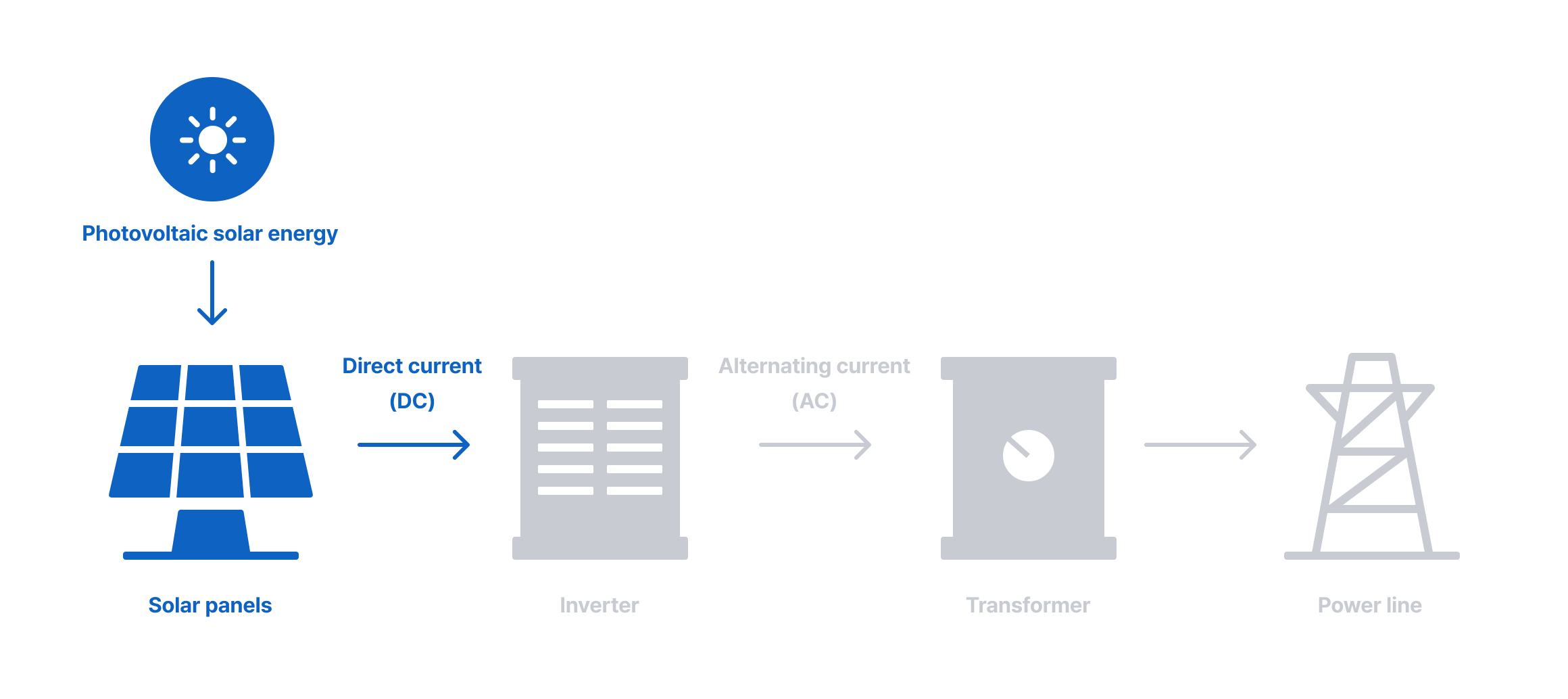

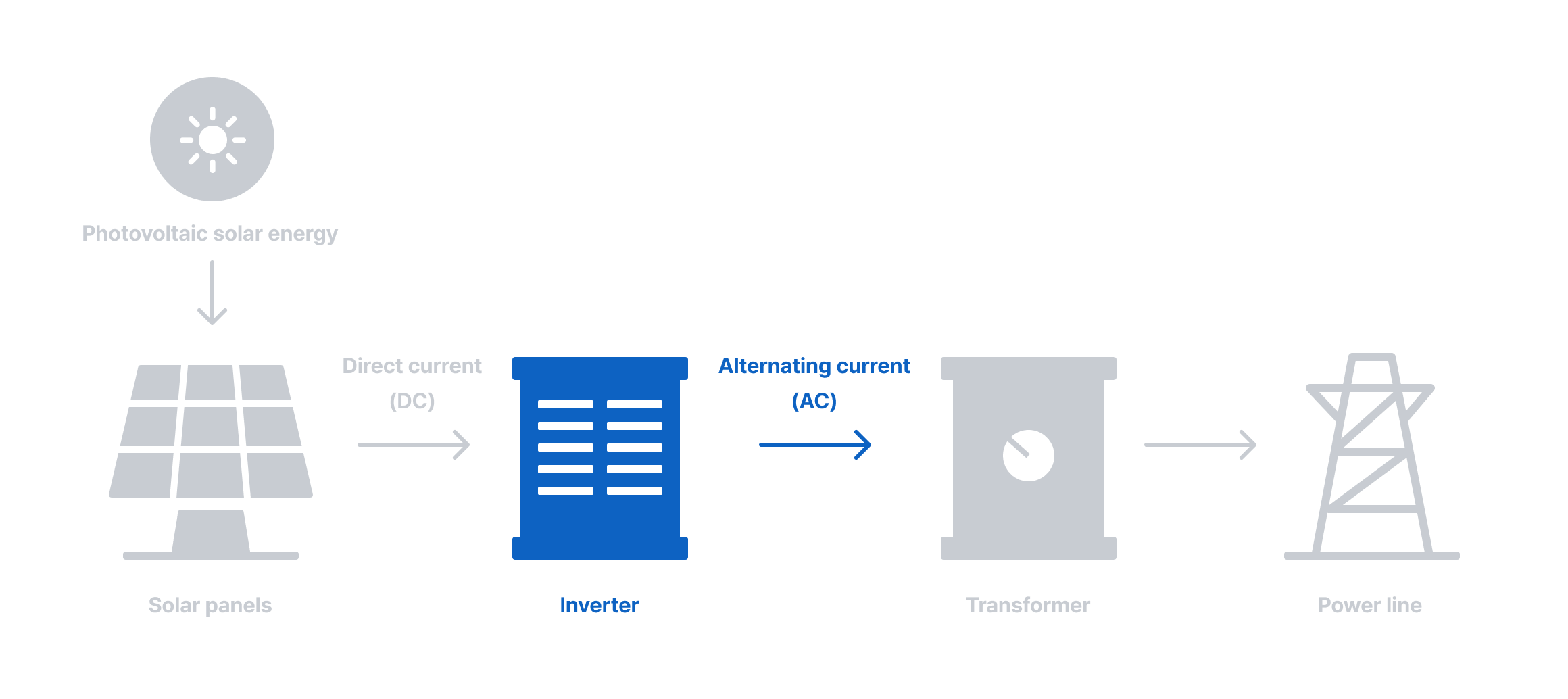

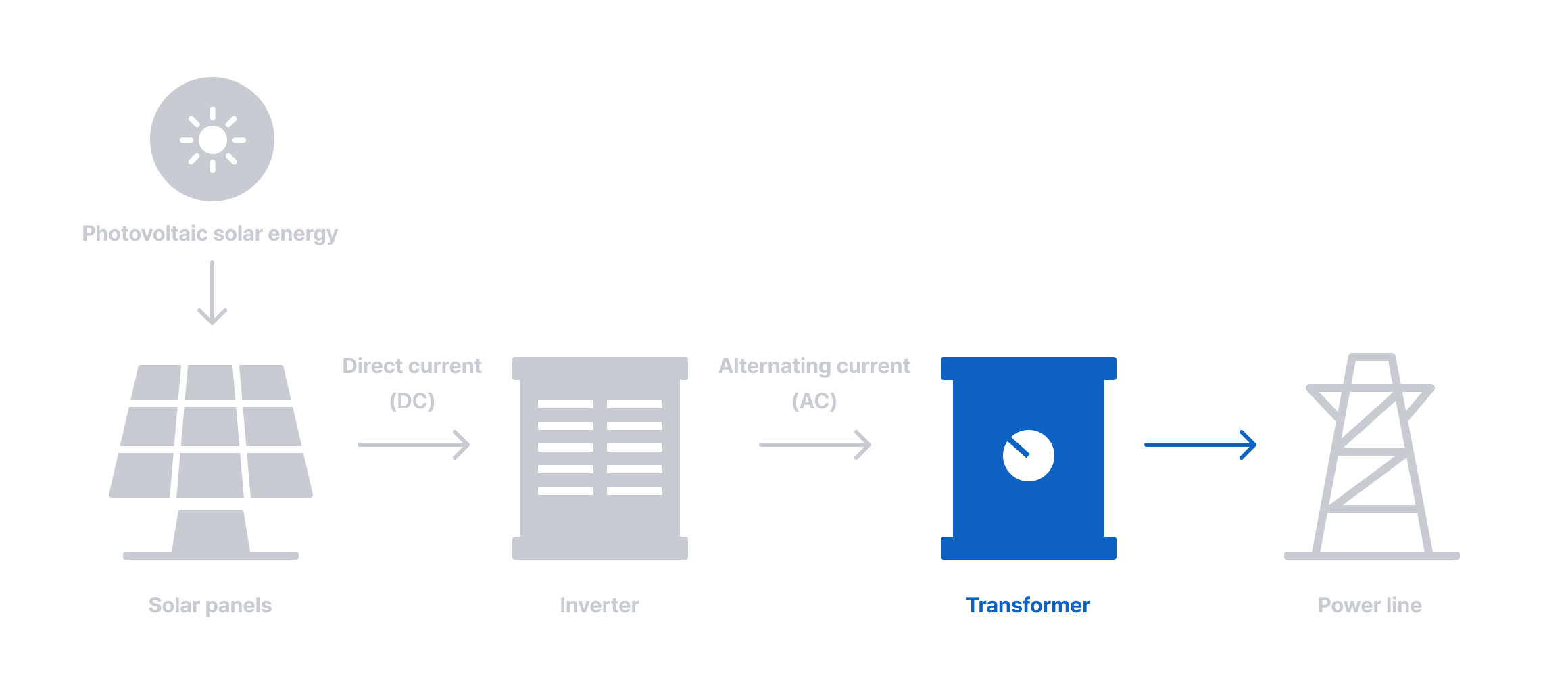

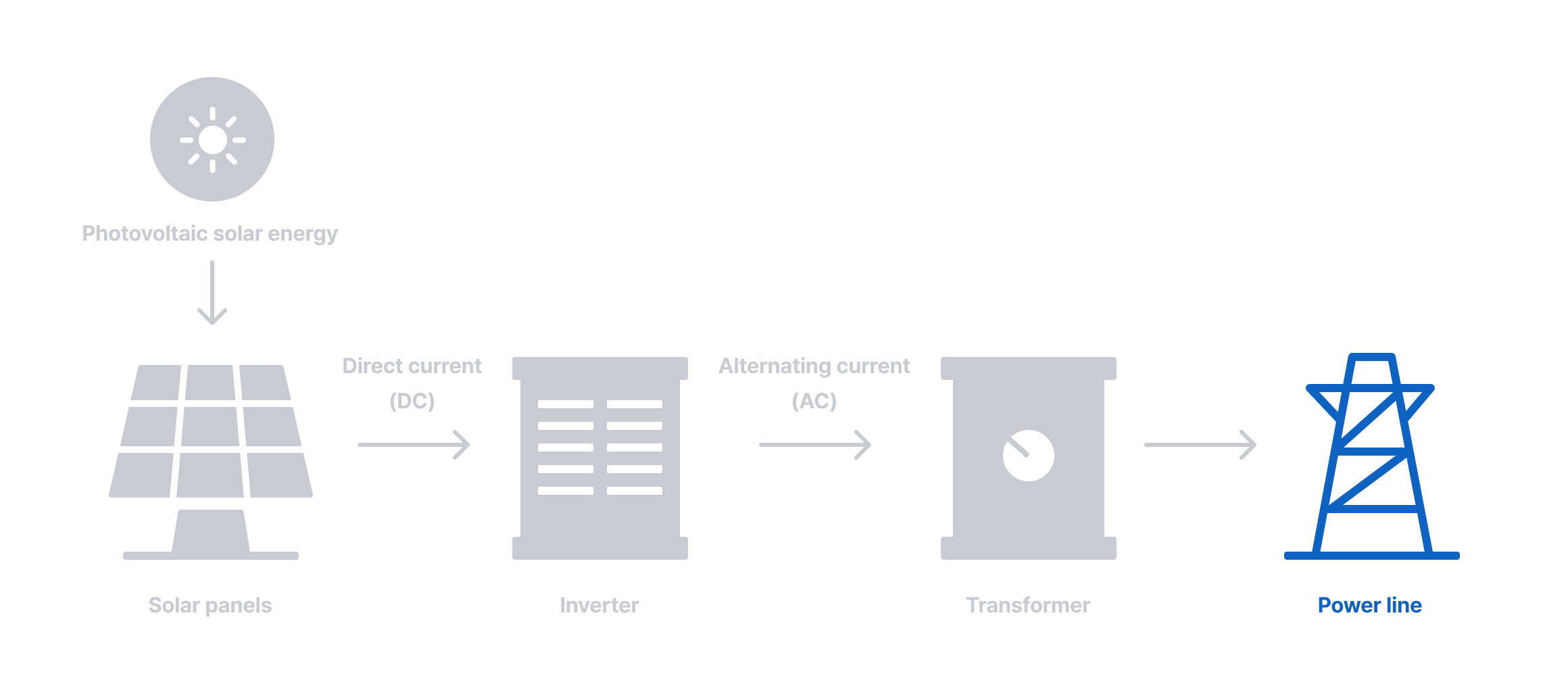

Power generation from renewable photovoltaic solar energy sources mitigates the effects of climate change by reducing greenhouse gas emissions. GS EPS protects the natural ecosystem by generating sustainable energy through photovoltaic power generation.

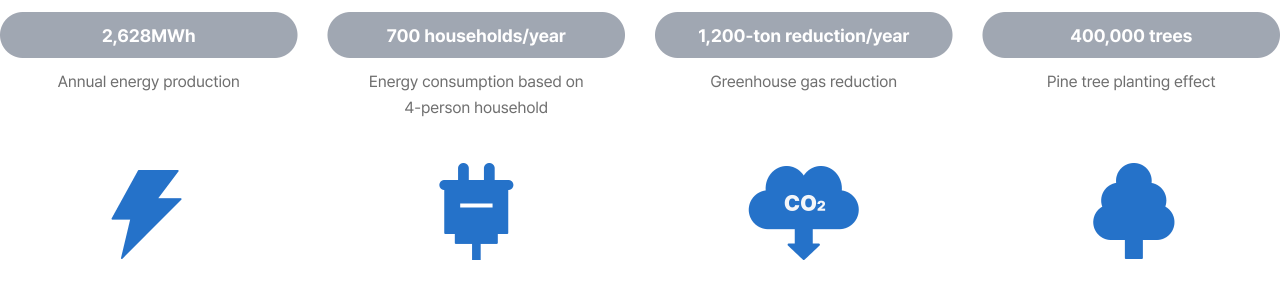

GS EPS generates eco-friendly energy through 2.0MW scaled photovoltaic power generation. It is equivalent to planting about 400,000 pine trees, reducing carbon dioxide by about 1,200 tons per year, making the earth greener.

Photovoltaic power generation is an eco-friendly method of generating electricity by converting light energy into electricity through solar panels.